Vacuum Insulated Phase Separator Series

Product Application

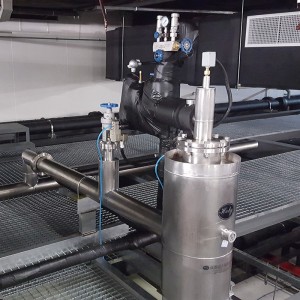

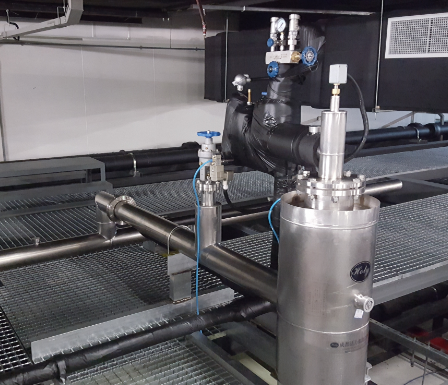

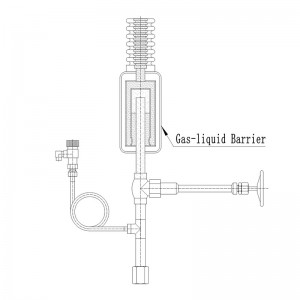

The Vacuum Insulated Phase Separator Series is an essential component in modern cryogenic systems, engineered to efficiently separate liquid and gaseous phases of cryogenic fluids while minimizing thermal losses. Designed for integration with Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Flexible Hoses, this series ensures reliable, thermally efficient fluid transfer and maintains optimal system performance under extreme conditions.

Key Applications and Benefits

-

Cryogenic Liquid Supply Systems

The Vacuum Insulated Phase Separator Series guarantees a consistent and pure liquid supply across complex cryogenic distribution networks. When paired with VIPs and VIHs, it minimizes pressure fluctuations and prevents vapor contamination, ensuring smooth and reliable delivery to downstream equipment. -

Cryogenic Tank Filling and Emptying

During tank operations, Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Phase Separators work together to optimize the flow of liquid cryogens, prevent gas lock, and reduce boil-off. This precise phase management ensures that tanks are filled or emptied efficiently while maintaining product integrity. -

Cryogenic Process Control

In industrial or laboratory cryogenic processes, the Vacuum Insulated Phase Separator Series enables accurate regulation of liquid and gas phases. By integrating with Vacuum Insulated Valves and Dynamic Vacuum Pump Systems, operators can achieve precise control over process parameters, improving efficiency and maintaining consistent quality across applications. -

Cryogenic Research and Analysis

For research applications, including low-temperature physics experiments or materials testing, phase separation is critical to maintain experimental accuracy. Vacuum Insulated Hoses (VIHs) paired with Phase Separators allow for safe, leak-free transfer of cryogenic fluids, ensuring the reliability of measurements and experimental results.

Technical Excellence and Reliability

HL Cryogenics’ products, including Vacuum Insulated Phase Separators, Vacuum Insulated Pipes (VIPs), Vacuum Insulated Hoses (VIHs), Vacuum Insulated Valves, and Dynamic Vacuum Pump Systems, are manufactured with stringent technical standards. Every component is tested for thermal efficiency, mechanical reliability, and operational safety, making them suitable for high-demand cryogenic applications, from industrial processes to advanced research facilities.

By choosing HL Cryogenics, engineers and researchers can trust in superior performance, reduced thermal losses, and seamless integration across all cryogenic distribution systems. The combination of VIPs, VIHs, and Vacuum Insulated Phase Separators ensures a complete solution for efficient, safe, and reliable cryogenic fluid management.

Vacuum Insulated Phase Separator

The Vacuum Insulated Phase Separator Series is an essential component in modern cryogenic systems, engineered to efficiently separate liquid and gaseous phases of cryogenic fluids while minimizing thermal losses. Designed for integration with Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Flexible Hoses (VIHs), this series ensures reliable, thermally efficient fluid transfer and maintains optimal system performance under extreme conditions.

Key Applications and Benefits

-

Cryogenic Liquid Supply Systems

The Vacuum Insulated Phase Separator Series guarantees a consistent and pure liquid supply across complex cryogenic distribution networks. When paired with Vacuum Insulated Pipes (VIPs) and VIHs, it minimizes pressure fluctuations and prevents vapor contamination, ensuring smooth and reliable delivery to downstream equipment. -

Cryogenic Tank Filling and Emptying

During tank operations, Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Phase Separators work together to optimize the flow of liquid cryogens, prevent gas lock, and reduce boil-off. This precise phase management ensures that tanks are filled or emptied efficiently while maintaining product integrity. -

Cryogenic Process Control

In industrial or laboratory cryogenic processes, the Vacuum Insulated Phase Separator Series enables accurate regulation of liquid and gas phases. By integrating with Vacuum Insulated Valves and Dynamic Vacuum Pump Systems, operators can achieve precise control over process parameters, improving efficiency and maintaining consistent quality across applications. -

Cryogenic Research and Analysis

For research applications, including low-temperature physics experiments or materials testing, phase separation is critical to maintain experimental accuracy. Vacuum Insulated Flexible Hoses (VIHs) paired with Vacuum Insulated Phase Separators allow for safe, leak-free transfer of cryogenic fluids, ensuring the reliability of measurements and experimental results.

Technical Excellence and Reliability

HL Cryogenics’ products, including Vacuum Insulated Phase Separators, Vacuum Insulated Pipes (VIPs), Vacuum Insulated Flexible Hoses (VIHs), Vacuum Insulated Valves, and Dynamic Vacuum Pump Systems, are manufactured with stringent technical standards. Every component is tested for thermal efficiency, mechanical reliability, and operational safety, making them suitable for high-demand cryogenic applications, from industrial processes to advanced research facilities.

By choosing HL Cryogenics, engineers and researchers can trust in superior performance, reduced thermal losses, and seamless integration across all cryogenic distribution systems. The combination of VIPs, VIHs, and Vacuum Insulated Phase Separators ensures a complete solution for efficient, safe, and reliable cryogenic fluid management.

Parameter Information

| Name | Degasser |

| Model | HLSP1000 |

| Pressure Regulation | No |

| Power Source | No |

| Electric Control | No |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 8~40L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 265 W/h (when 40L) |

| Heat Loss When Is Stable | 20 W/h (when 40L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Phase Separator |

| Model | HLSR1000 |

| Pressure Regulation | Yes |

| Power Source | Yes |

| Electric Control | Yes |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 8L~40L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 265 W/h (when 40L) |

| Heat Loss When Is Stable | 20 W/h (when 40L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Automatic Gas Vent |

| Model | HLSV1000 |

| Pressure Regulation | No |

| Power Source | No |

| Electric Control | No |

| Automatic Working | Yes |

| Design Pressure | ≤25bar (2.5MPa) |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | 4~20L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 190W/h (when 20L) |

| Heat Loss When Is Stable | 14 W/h (when 20L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description |

|

| Name | Special Phase Separator for MBE Equipment |

| Model | HLSC1000 |

| Pressure Regulation | Yes |

| Power Source | Yes |

| Electric Control | Yes |

| Automatic Working | Yes |

| Design Pressure | Determine according to MBE Equipment |

| Design Temperature | -196℃~ 90℃ |

| Insulation Type | Vacuum Insulation |

| Effective Volume | ≤50L |

| Material | 300 Series Stainless Steel |

| Medium | Liquid Nitrogen |

| Heat Loss When Filling LN2 | 300 W/h (when 50L) |

| Heat Loss When Is Stable | 22 W/h (when 50L) |

| Vacuum of Jacketed Chamber | ≤2×10-2Pa (-196℃) |

| Leakage Rate of Vacuum | ≤1×10-10Pa.m3/s |

| Description | A Special Phase Separator for MBE equipment with Multiple Cryogenic Liquid Inlet and Outlet with automatic control function meets the requirement of gas emission, recycled liquid nitrogen and temperature of liquid nitrogen. |