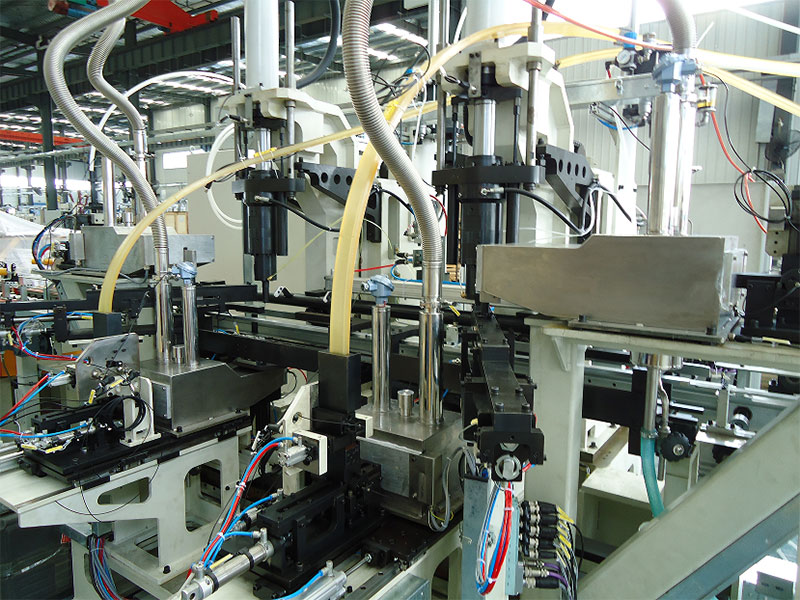

The liquid nitrogen flume/tank, (Dynamic) Vacuum Insulated (Flexible) Piping Systems, Vacuum Insulated Valves and Vacuum Phase Separators are needed for cryogenic assembly of automobile engine. Cryogenic assembly of automobile engine parts has many advantages to compare with the traditional assembly process. Now it has been widely used in automobile engines and electric motor manufacturing plants.

HL Cryogenic Equipment has 15 years of experience in the automobile engine industry and electromotor industry. Accumulated a lot of experience and knowledge, with the capability of "discovering customer problems", "solving customer problems" and "improving customer systems".

Cryogenic assembly has many advantages over traditional heating assembly. In traditional heating assembly, parts are in unstable state during heating process and assembly process under high temperature condition. After returning to normal temperature and later use, deformation is more likely to occur.

The common problems of Vacuum Insulated Piping System in cryogenic assembly include,

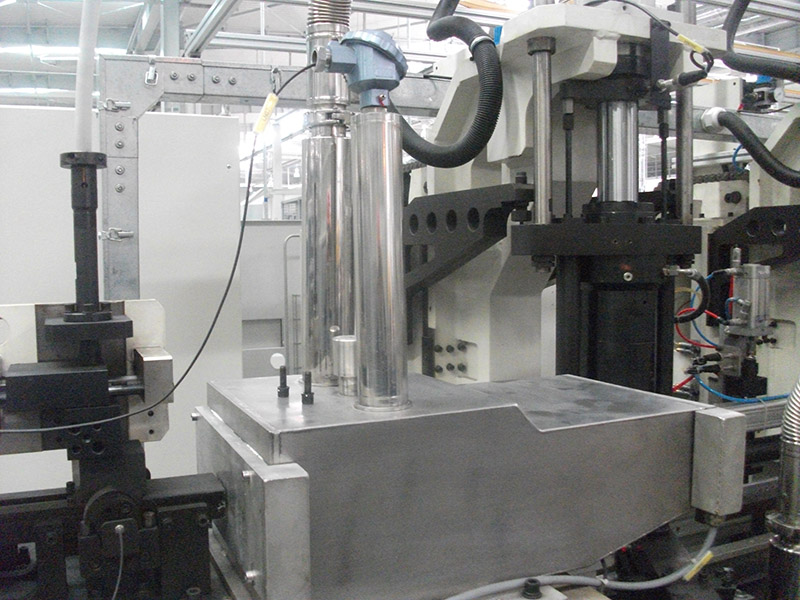

- Customized design for liquid nitrogen flume/tank which as an important and special part is the core of the cooling process of the whole cryogenic assembly of engine.

- Cooling Time and Automatic Control Procedures of Automobile engine parts

- The Temperature of Liquid Nitrogen into Terminal Equipment

- (Automatic) Switching of Main and Branch Lines

- Pressure Adjustment (Reducing) and Stability of VIP

- Cleaning Away the Possible Impurities and Ice Residue from Tank

- Pipeline Precooling

- Liquid Resistance in VIP System

HL's Vacuum Insulated Pipe (VIP) is built to ASME B31.3 Pressure Piping code as a standard. Engineering experience and quality control ability to ensure the efficiency and cost-effectiveness of the customer's plant.

Related Products

FAMOUS CUSTOMERS

- Volkswagen

- Comau

- Hyundai

- Dongfeng Automobile

SOLUTIONS

HL Cryogenic Equipment provides customers with the Vacuum Insulated Piping System to meet the requirements and conditions of the Automobile Engine and Electromotor Industry:

1.Quality Management System: ASME B31.3 Pressure Piping Code.

2.According to the user's freezing time and the movement of the manipulator, the reasonable design is carried out.

3.Reasonable design and placement of Phase Separator in the VI Piping System is the key to ensure the stability and satisfaction of liquid pressure and temperature.

4.The Vacuum Insulated Valve (VIV) Series Available: Including Vacuum Insulated (Pneumatic) Shut-off Valve, Vacuum Insulated Check Valve, Vacuum Insulated Regulating Valve etc. Various types of VIV can be modular combined to control the VIP as required. VIV is integrated with VIP prefabrication in manufacturer, without on-site Insulated treatment. The seal unit of VIV can be replaced easily. (HL accepts the cryogenic valve brand designated by customers, and then makes vacuum insulated valves by HL. Some brands and models of valves may not be able to be made into vacuum insulated valves.)

5.Cleanliness, if there are additional requirements for inner tube surface cleanliness. It is suggested that customers choose BA or EP stainless steel pipes as VIP inner pipes to further reduce stainless steel spillage.

6.Vacuum Insulated Filter: Clean away the possible impurities and ice residue from tank.

7.After a few days or longer shutdown or maintenance, it is very necessary to precool the VI Piping and terminal equipment before cryogenic liquid is entered, so as to avoid ice slag after cryogenic liquid directly enters the VI Piping and terminal equipment. Precooling function should be considered in design. It provides better protection for terminal equipment and VI Piping support equipment such as valves.

8.Suit for both Dynamic and Static Vacuum Insulated (Flexible) Piping System.

9.Dynamic Vacuum Insulated (Flexible) Piping System: Consist of VI Flexible Hoses and/or VI Pipe, Jumper Hoses, Vacuum Insulated Valve System, Phase Separators and Dynamic Vacuum Pump System (including the vacuum pumps, solenoid valves and vacuum gauges etc.). The length of single VI Flexible Hose can be customized according to user’s requirements.

10.Various Connection Types: Vacuum Bayonet Connection (VBC) Type and Welded Connection can be selected. The VBC type do not need on-site insulated treatment.