Introduction to Vacuum Insulated Pipes in Liquid Oxygen Transport

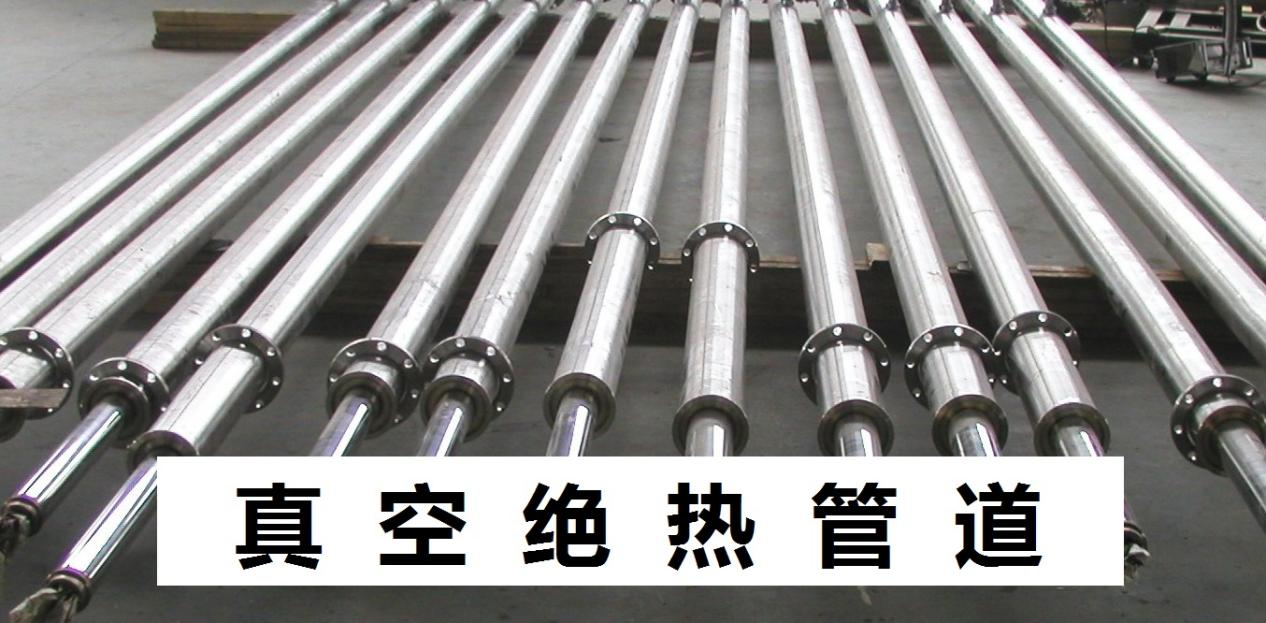

Vacuum insulated pipes (VIPs) are essential for the safe and efficient transport of liquid oxygen, a highly reactive and cryogenic substance used in various industries, including medical, aerospace, and industrial sectors. The unique properties of liquid oxygen require specialized handling and transport systems to maintain its low temperature and prevent any phase change. Vacuum insulated pipes are specifically designed to meet these demands, making them indispensable in applications involving liquid oxygen.

The Importance of Temperature Control in Liquid Oxygen Transport

Liquid oxygen must be stored and transported at temperatures below its boiling point of -183°C (-297°F) to remain in its liquid state. Any increase in temperature can lead to vaporization, which poses safety risks and can result in significant product loss. Vacuum insulated pipes offer a reliable solution to this challenge by minimizing heat transfer. The vacuum layer between the inner and outer pipes acts as an effective thermal barrier, ensuring that liquid oxygen remains at the required low temperature during transit.

Introduction to Vacuum Insulated Pipes in Liquid Oxygen Transport

Vacuum insulated pipes (VIPs) are essential for the safe and efficient transport of liquid oxygen, a highly reactive and cryogenic substance used in various industries, including medical, aerospace, and industrial sectors. The unique properties of liquid oxygen require specialized handling and transport systems to maintain its low temperature and prevent any phase change. Vacuum insulated pipes are specifically designed to meet these demands, making them indispensable in applications involving liquid oxygen.

The Importance of Temperature Control in Liquid Oxygen Transport

Liquid oxygen must be stored and transported at temperatures below its boiling point of -183°C (-297°F) to remain in its liquid state. Any increase in temperature can lead to vaporization, which poses safety risks and can result in significant product loss. Vacuum insulated pipes offer a reliable solution to this challenge by minimizing heat transfer. The vacuum layer between the inner and outer pipes acts as an effective thermal barrier, ensuring that liquid oxygen remains at the required low temperature during transit.

Post time: Jun-11-2025