OEM Cryogenic Insulated Filter

Exceptional Filtration Efficiency in Cryogenic Environments: Our OEM Cryogenic Insulated Filter is specifically designed to deliver exceptional filtration performance in cryogenic environments, ensuring the purity and integrity of processes in industrial applications. With advanced insulation technology, it maintains filtration efficiency even in extremely low temperatures, making it an ideal choice for critical cryogenic filtration requirements.

Customizable Options for Diverse Industrial Requirements: Recognizing the diverse needs of industrial applications, our OEM Cryogenic Insulated Filter offers customizable options. This includes variations in filter size, media selection, connection types, and insulation materials, allowing for tailored solutions that seamlessly integrate into different cryogenic systems while meeting specific industrial requirements.

Precision Manufacturing and Stringent Quality Control: Produced in our cutting-edge manufacturing facility, the OEM Cryogenic Insulated Filter undergoes precision engineering and stringent quality control processes to ensure unparalleled performance and reliability. Our commitment to excellence in manufacturing and the use of high-grade materials guarantee longevity and superior filtration performance, making it a trusted choice for critical cryogenic applications.

Product Application

The all series of vacuum insulated equipment in HL Cryogenic Equipment Company, which passed through a series of extremely strict technical treatments, are used for transferring of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (cryogenic tanks and dewar flasks etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, pharmacy, hospital, biobank, food & beverage, automation assembly, rubber, new material manufacturing and scientific research etc.

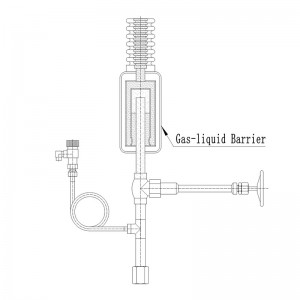

Vacuum Insulated Filter

The Vacuum Insulated Filter, namely Vacuum Jacketed Filter, is used to filter impurities and possible ice residue from liquid nitrogen storage tanks.

The VI Filter can effectively prevent the damage caused by impurities and ice residue to the terminal equipment, and improve the service life of the terminal equipment. In particular, it is strongly recommend for high value terminal equipment.

The VI Filter is installed in front of main line of VI pipeline. In the manufacturing plant, the VI Filter and VI Pipe or Hose are prefabricated into one pipeline, and there is no need for installation and insulated treatment on site.

The reason why the ice slag appears in the storage tank and vacuum jacketed piping is that when the cryogenic liquid is filled at the first time, the air in the storage tanks or VJ piping is not exhausted in advance, and the moisture in the air freezes when it gets cryogenic liquid. Therefore, it is highly recommended to purge the VJ piping for the first time or for the recovery of the VJ piping when it is injected with cryogenic liquid. Purge can also effectively remove the impurities deposited inside the pipeline. However, installing a vacuum insulated filter is a better option and double safe measure.

For more personalized and detailed questions, please contact HL Cryogenic Equipment Company directly, we will serve you whole-heartedly!

Parameter Information

| Model | HLEF000 Series |

| Nominal Diameter | DN15 ~ DN150 (1/2" ~ 6") |

| Design Pressure | ≤40bar (4.0MPa) |

| Design Temperature | 60℃ ~ -196℃ |

| Medium | LN2 |

| Material | 300 Series Stainless Steel |

| On-site Installation | No |

| On-site Insulated Treatment | No |