Vacuum Insulated Filter

Product Application

The Vacuum Insulated Filter is a crucial component within cryogenic systems, designed to remove particulate contaminants from cryogenic fluids, ensuring system purity and preventing damage to downstream equipment. Designed to work in tandem with a Vacuum Insulated Pipe (VIP) and Vacuum Insulated Hose (VIH), The HL Cryogenics team will keep you clear and free.

Key Applications:

- Cryogenic Liquid Transfer Systems: Installed within Vacuum Insulated Pipe (VIP) and Vacuum Insulated Hose (VIH), the Vacuum Insulated Filter safeguards pumps, valves, and other sensitive components from damage caused by particulate contamination.

- Cryogenic Storage and Dispensing: The Vacuum Insulated Filter maintains the purity of cryogenic liquids within storage tanks and dispensing systems, preventing contamination of sensitive processes and experiments. These also work with Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs).

- Cryogenic Processing: In cryogenic processes such as liquefaction, separation, and purification, the Vacuum Insulated Filter removes contaminants that could compromise product quality.

- Cryogenic Research: This also provides great purity.

HL Cryogenics' entire range of vacuum-insulated equipment, including the Vacuum Insulated Filter, undergoes rigorous technical testing to ensure exceptional performance in demanding cryogenic applications.

Vacuum Insulated Filter

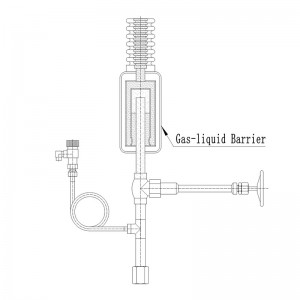

The Vacuum Insulated Filter, also known as the Vacuum Jacketed Filter, is designed to remove impurities and potential ice residue from liquid nitrogen storage tanks, ensuring the purity of your cryogenic fluids. It’s an extremely vital addition to your cryogenic equipment.

Key Benefits:

- Equipment Protection: Effectively prevents damage to terminal equipment caused by impurities and ice, extending equipment lifespan. This works extremely well in a Vacuum Insulated Pipe and Vacuum Insulated Hose.

- Recommended for High-Value Equipment: Provides an extra layer of protection for critical and expensive terminal equipment and all of your cryogenic equipment.

The Vacuum Insulated Filter is installed inline, typically upstream of the main line of a Vacuum Insulated pipeline. To simplify installation, the Vacuum Insulated Filter and Vacuum Insulated Pipe or Vacuum Insulated Hose can be prefabricated as a single unit, eliminating the need for on-site insulation. HL Cryogenics provides the best products to combine with your cryogenic equipment.

Ice slag formation in storage tanks and vacuum jacketed piping can occur when air is not fully purged before the initial cryogenic liquid fill. Moisture in the air freezes upon contact with the cryogenic liquid.

While purging the system before initial fill or after maintenance can effectively remove impurities, a Vacuum Insulated Filter provides a superior, double-safe measure. This keeps performance high with cryogenic equipment.

For detailed information and personalized solutions, please contact HL Cryogenics directly. We are committed to providing expert guidance and exceptional service.

Parameter Information

| Model | HLEF000 Series |

| Nominal Diameter | DN15 ~ DN150 (1/2" ~ 6") |

| Design Pressure | ≤40bar (4.0MPa) |

| Design Temperature | 60℃ ~ -196℃ |

| Medium | LN2 |

| Material | 300 Series Stainless Steel |

| On-site Installation | No |

| On-site Insulated Treatment | No |