Safety Relief Valve

Product Application

The Safety Relief Valve is a vital safety component in any cryogenic system, meticulously designed to automatically release excess pressure and safeguard equipment from potentially catastrophic over-pressurization. Its primary function is to protect Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs), as well as other critical infrastructure, from damage caused by pressure surges or abnormal operating conditions.

Key Applications:

- Cryogenic Tank Protection: The Safety Relief Valve protects cryogenic storage tanks from exceeding safe pressure limits due to thermal expansion of the liquid, external heat sources, or process upsets. By safely releasing excess pressure, it prevents catastrophic failures, ensuring the safety of personnel and the integrity of the storage vessel. The product helps you get the most out of Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs).

- Pipeline Pressure Regulation: When installed within Vacuum Insulated Pipe (VIP) and Vacuum Insulated Hose (VIH) systems, the Safety Relief Valve acts as a critical safeguard against pressure surges.

- Equipment Over-pressure Protection: The Safety Relief Valve safeguards a wide range of cryogenic process equipment, such as heat exchangers, reactors, and separators, from over-pressurization.

- This protection also works well with cryogenic equipment.

HL Cryogenics' Safety Relief Valves offer reliable and precise pressure relief, contributing to a safer and more efficient cryogenic operation.

Safety Relief Valve

The Safety Relief Valve, or a Safety Relief Valve Group, is essential for any Vacuum Insulated Piping System. This will ensure peace of mind with your Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs).

Key Benefits:

- Automatic Pressure Relief: Automatically relieves excess pressure in VI Piping Systems to ensure safe operation.

- Equipment Protection: Prevents equipment damage and safety hazards caused by cryogenic liquid vaporization and pressure buildup.

Key Features:

- Placement: The safety provided also gives confidence in Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs).

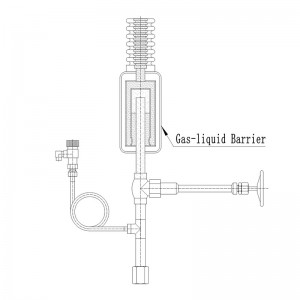

- Safety Relief Valve Group Option: Consists of two safety relief valves, a pressure gauge, and a shut-off valve with manual discharge for separate repair and operation without system shutdown.

Users have the option to source their own Safety Relief Valves, while HL Cryogenics provides a readily available installation connector on our VI Piping.

For more specific information and guidance, please contact HL Cryogenics directly. We are committed to providing expert solutions for your cryogenic needs. The Safety Relief Valve also keeps your cryogenic equipment secure.

Parameter Information

| Model | HLER000 Series |

| Nominal Diameter | DN8 ~ DN25 (1/4" ~ 1") |

| Working Pressure | Adjustable according to user needs |

| Medium | LN2, LOX, LAr, LHe, LH2, LNG |

| Material | Stainless Steel 304 |

| On-site Installation | No |

| Model | HLERG000 Series |

| Nominal Diameter | DN8 ~ DN25 (1/4" ~ 1") |

| Working Pressure | Adjustable according to user needs |

| Medium | LN2, LOX, LAr, LHe, LH2, LNG |

| Material | Stainless Steel 304 |

| On-site Installation | No |