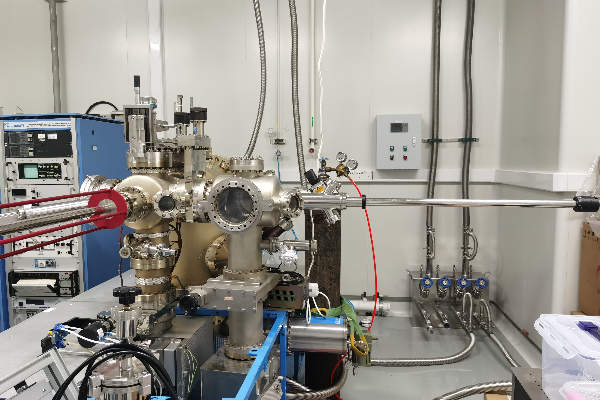

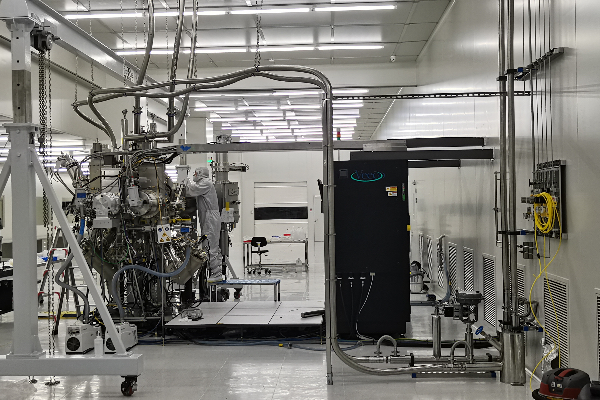

Introduction to Vacuum Insulated Phase Separators

Vacuum insulated Phase Separators are critical for ensuring that cryogenic pipelines deliver liquid rather than gas. They separate vapor from liquid in LN₂, LOX, or LNG systems, maintaining stable flow, minimizing losses, and improving overall efficiency.

Importance in Cryogenic Operations

In pipelines without vacuum insulated Phase Separators, gas bubbles can form, causing unstable pressure and inconsistent liquid flow. This affects LNG terminals, semiconductor facilities, aerospace fueling systems, and biopharmaceutical cold chains. Using vacuum insulated phase separators ensures smooth, reliable cryogenic liquid delivery.

Key Benefits of Vacuum Insulated Phase Separators

Maintain steady cryogenic performance across pipelines.

Minimize nitrogen or LNG loss, reducing operating costs.

Enhance operational safety and system reliability.

Enable integration with Vacuum Insulated Pipes (VIPs), Vacuum Insulated Hoses (VIHs), and Valves for turnkey solutions.

Choosing a Manufacturer for Vacuum Insulated Phase Separators

Selecting a professional vacuum insulated Phase Separators manufacturer is crucial. HL Cryogenics, one of China’s top cryogenic equipment suppliers, provides high-quality phase separators for LNG, LN₂, and other cryogenic applications. Their engineering expertise ensures every system meets industry standards for efficiency, safety, and long-term durability.

Conclusion

Vacuum insulated Phase Separators are essential for maintaining performance and safety in cryogenic systems. HL Cryogenics’ solutions optimize liquid delivery, reduce losses, and provide reliable support for industries ranging from LNG to aerospace to biopharma.

Post time: Sep-17-2025