Liquefied hydrogen is really shaping up to be a key player in the global move towards cleaner energy, with the power to seriously change how our energy systems work worldwide. But, getting liquefied hydrogen from point A to point B is far from simple. Its super-low boiling point and the fact that it’s really sensitive to any heat getting in create some major technical headaches that need solving to keep things safe and efficient during transport.

This is exactly where HL Cryogenics really shines. The company’s whole lineup of advanced products – like their Vacuum Insulated Pipes (VIPs), Vacuum Insulated Hoses (VIHs), Vacuum Insulated Valves, and Phase Separators – offers a complete answer to the complex challenges of moving hydrogen around. These vacuum-insulated systems are purpose-built to minimize heat transfer. What that means is they keep hydrogen in its liquid form, massively cutting down on losses from evaporation. The outcome? Not only do you preserve the product’s purity, but you also see significant savings on costs because less is evaporating away.

For quite a few decades now, HL Cryogenics has been building a name for itself as a leader in cryogenic tech. Their vacuum-insulated piping systems are now a pretty common sight in hydrogen projects all over the world. While older transfer systems often deal with a lot of cold loss and safety risks, HL Cryogenics’ technologies have really set a new benchmark for reliability and keeping things contained. Their flexible hose series, in particular, adds a lot of practical adaptability for different loading and unloading situations, making hydrogen distribution networks much more manageable.

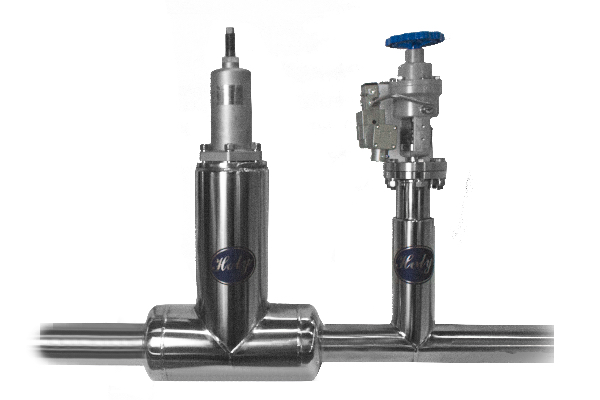

When it comes to hydrogen infrastructure, safety and stability are absolutely non-negotiable. HL Cryogenics’ vacuum-insulated valve series provides exact control over flow and reliable leak prevention, even under really extreme cryogenic conditions. The Phase Separators series takes it a step further by ensuring you’re getting hydrogen in its purest state, which really optimizes both efficiency and how you use your resources. When you combine all this with HL Cryogenics’ dynamic vacuum pump systems and their specialized support gear, clients end up with a solid, all-in-one solution that covers every aspect of getting liquefied hydrogen from here to there.

As governments and industries get more serious about carbon neutrality, the need for better ways to transport hydrogen is only going to pick up speed. By tapping into HL Cryogenics’ advanced vacuum-insulated technologies, companies are much better equipped to meet their sustainability goals, find cost efficiencies, and stick to those strict safety rules all along the hydrogen supply chain. HL’s ongoing work in vacuum insulation is set to be a really important part of how we handle clean energy logistics in the future.

Post time: Sep-04-2025