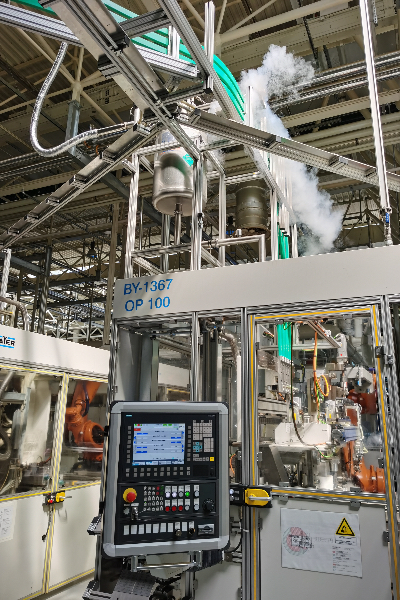

HL Cryogenics stands out as a top name in advanced cryogenic systems. Our main products— Vacuum Insulated Pipe, Vacuum Insulated Flexible Hose, Dynamic Vacuum Pump System, Vacuum Insulated Valve, and Vacuum Insulated Phase Separator—form the backbone of our work. We’ve designed every component to handle the tough job of transferring cryogenic liquids like liquid nitrogen, liquid oxygen, and LNG. These products keep thermal losses low, keep operations safe, and deliver steady performance, even when the conditions get rough.

Take our Vacuum Insulated Pipe series. Each pipe comes with a double-wall design and a high-vacuum layer in between, plus extra insulation to keep heat out. The result? These pipes move cryogenic liquids with barely any boil-off, which means less waste and better efficiency. Our flexible hoses fit right in, filling the gaps where you need mobility or have to make quick changes. They bend and move without giving up vacuum strength or thermal performance.

The Dynamic Vacuum Pump System is the unsung hero here. It keeps the vacuum strong between pipe walls and inside hoses, making sure insulation stays top-notch. It runs continuously, doesn’t need much fuss, and helps keep the whole system dependable for the long haul. Our Vacuum Insulated Valves give you tight control over flow and pressure—essential when you’re moving cryogenic fluids in serious environments like LNG terminals or research labs. Meanwhile, the Phase Separators clear out vapor, so you get a steady liquid supply without annoying interruptions.

We don’t just chase performance—we make things safe and easy to maintain, too. Every part is built from top-quality stainless steel for strength and chemical compatibility. Our vacuum insulation goes through tough testing and packs in safety features to avoid any nasty cryogenic surprises. We design piping layouts to save space and cut down on thermal stress, while hoses and valves get pressure-tested and certified before they leave our hands.

Maintaining our systems is straightforward. Modular parts and easy-access vacuum ports mean checks and fixes don’t drag out. Regular inspections and vacuum monitoring keep everything running right, and the Dynamic Vacuum Pump System automatically keeps the vacuum at its best. All this engineering, precision, and reliability make HL Cryogenics a go-to partner for demanding projects that can’t compromise on safety or performance.

If you’re an engineer or project lead looking to get more out of your liquid nitrogen or cryogenic operations, we’ve got you covered. From Vacuum Insulated Pipes and Vacuum Insulated Flexible Hoses to Vacuum Insulated Valves and Vacuum Insulated Phase Separator, we’ll customize solutions to fit your needs—backed by deep expertise in LN₂ systems, vacuum insulation, and cryogenic engineering. Reach out to HL Cryogenics and let’s build a cryogenic piping system that’s safer, more efficient, and cost-effective for whatever you’re working on.

Post time: Nov-24-2025