The whole cryogenics game is really about keeping things cold, and cutting down on energy waste is a huge part of that. When you think about how much industries now rely on things like liquid nitrogen, oxygen, and argon, it makes total sense why controlling those losses during storage and transfer is so critical. Here at HL Cryogenics, we’re all about tackling cold loss head-on, especially with our Vacuum Insulated Pipe (VIP) systems. They’re designed from the ground up to drastically cut down on that unwanted heat gain. It’s not just about making systems more dependable and eco-friendly; it’s about saving our clients real money too.

So, what exactly is cold loss? Basically, it’s when your super-cold liquids pick up heat from their surroundings while they’re sitting in storage or being moved around. This heat makes them evaporate, and that’s energy down the drain. Whether you’re in healthcare, flying rockets, freezing food, or doing cutting-edge science, even a little bit of cold loss can really mess with efficiency. It’s not just about how well your gear performs; it’s about managing costs and being kinder to the planet.

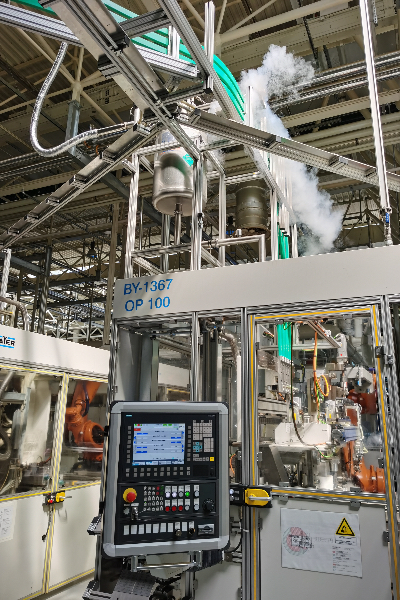

What makes our Vacuum Insulated Pipe (VIPs) and Vacuum Insulated Hoses (VIHs) stand out? It’s really the advanced insulation and that super-high vacuum we pack in there, which does a fantastic job of keeping heat from sneaking in. This keeps your cryogenic liquids stable during transfer, meaning less evaporation. We’ve really fine-tuned the design of our Vacuum Insulated Pipe (VIP) systems to make them more energy-efficient and reliable over the long haul.

And it’s not just the pipes and hoses. You’ve also got to consider the supporting players – like phase separators and our vacuum insulated valves. Phase separators are key for keeping things in the ideal liquid-gas balance inside the pipe, stopping that pesky boil-off. Our precision valves then carefully control the flow, minimizing how much they’re even exposed to outside heat. Everything is built to work together, creating a system that’s really all about maximizing efficiency.

When you look at energy efficiency and sustainability in cryogenics, they’re pretty much tied together. We’re really committed here at HL Cryogenics to finding solutions that not only save your precious cryogenic materials but also lower your facility’s overall energy bill. By using our optimized Vacuum Insulated Pipe (VIP) systems, companies can see a real difference in their bottom line and also feel good about being more environmentally responsible.

Looking ahead, the direction cryogenics is taking is all about smarter, more efficient gear. By zeroing in on cold loss with advanced Vacuum Insulated Pipes (VIPs), Vacuum Insulated Hoses (VIHs), Vacuum Insulated Valves, and Phase Separators, HL Cryogenics is helping industries run safer, be more efficient, and generally move towards a more sustainable future.

Post time: Aug-26-2025