Gas Lock

Product Application

The Gas Lock is a highly effective component designed to prevent flow disruptions caused by gas lock within cryogenic transfer lines. It’s an essential addition to any system utilizing Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs), ensuring a consistent and reliable supply of cryogenic fluids. This is important when dealing with your cryogenic equipment.

Key Applications:

- Cryogenic Liquid Transfer: The Gas Lock ensures a continuous, uninterrupted flow of cryogenic liquid through Vacuum Insulated Pipe and Vacuum Insulated Hose systems. It automatically detects and relieves accumulated gas pockets, preventing flow restrictions and maintaining optimal transfer rates.

- Cryogenic Equipment Supply: Guarantees a consistent liquid flow to cryogenic equipment, optimizing system performance and preventing equipment malfunctions that can result from inconsistent cryogenic fluid delivery. The safety provided also gives confidence in Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs).

- Cryogenic Storage Systems: By preventing gas lock in fill and drain lines, the Gas Lock maximizes the efficiency of cryogenic storage tank operations, reducing fill times and improving overall system throughput. The protection is great for your cryogenic equipment.

With HL Cryogenics' commitment to innovation and quality, you can be confident that our Gas Lock solutions will significantly enhance the performance, reliability, and safety of your cryogenic systems.

Vacuum Insulated Shut-off Valve

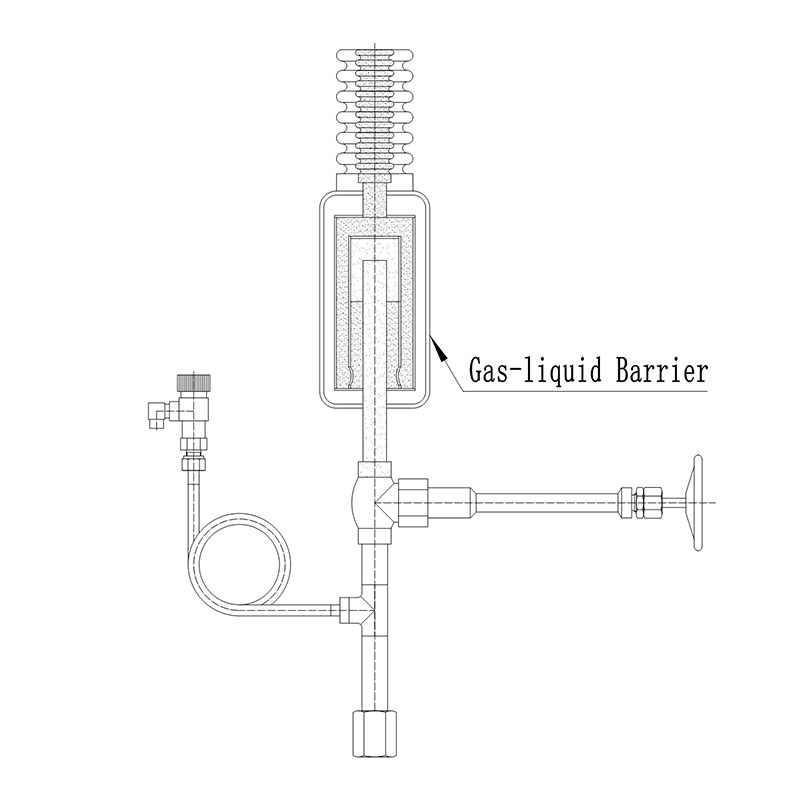

The Gas Lock is strategically placed within vertical Vacuum Jacketed (VJP) Pipes at the end of Vacuum Insulated Piping (VIP) systems. It’s an important measure to prevent the loss of liquid nitrogen. These pipes often include Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs). It is important to save money.

Key Benefits:

- Reduced Heat Transfer: Utilizes a gas seal to block heat transfer from the non-vacuum portion of the piping, minimizing liquid nitrogen vaporization. The design also works well with Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs).

- Minimized Liquid Nitrogen Loss: Significantly reduces liquid nitrogen losses during intermittent system use, resulting in cost savings.

A small, non-vacuum section typically connects the VJ piping to the terminal equipment. This creates a point of significant heat gain from the surrounding environment. The product keeps your cryogenic equipment running.

The Gas Lock limits heat transfer into the VJ piping, minimizing liquid nitrogen losses, and stabilizes pressure. The design also works well with Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs).

Features:

- Passive Operation: Requires no external power source.

- Prefabricated Design: The Gas Lock and Vacuum Insulated Pipe or Vacuum Insulated Hose are prefabricated as a single unit, eliminating the need for on-site installation and insulation.

For detailed information and customized solutions, please contact HL Cryogenics directly. We are dedicated to providing efficient and cost-effective solutions for your cryogenic needs.

Parameter Information

| Model | HLEB000 Series |

| Nominal Diameter | DN10 ~ DN25 (1/2" ~ 1") |

| Medium | LN2 |

| Material | 300 Series Stainless Steel |

| On-site Installation | No |

| On-site Insulated Treatment | No |