For over three decades, HL Cryogenics has specialized in advanced cryogenic applications, building a strong reputation through extensive cooperation on international projects. Over time, the company has developed a comprehensive Enterprise Standard and Quality Management System, aligned with global benchmarks for Vacuum Insulated Piping Systems (VIPs). This system includes a detailed quality manual, standardized procedures, operational instructions, and administrative rules—all continuously updated to reflect best practices and project requirements.

HL Cryogenics has successfully passed rigorous on-site audits by leading International Gas Companies, including Air Liquide, Linde, Air Products, Messer, and BOC. As a result, HL has been officially authorized to manufacture according to their strict project standards. The consistent quality of HL products has been recognized as meeting world-class performance levels.

The company maintains multiple international certifications, ensuring reliability and compliance:

-

ISO 9001 Quality Management System Certification, with ongoing revalidation audits.

-

ASME Qualification for welders, Welding Procedure Specifications (WPS), and Non-Destructive Inspection (NDI).

-

ASME Quality System Certification, demonstrating conformity to the highest engineering and safety requirements.

-

CE Marking Certification under the Pressure Equipment Directive (PED), confirming compliance with European safety and performance standards.

By integrating decades of expertise with internationally recognized certifications, HL Cryogenics delivers solutions that combine engineering precision, operational safety, and global trust.

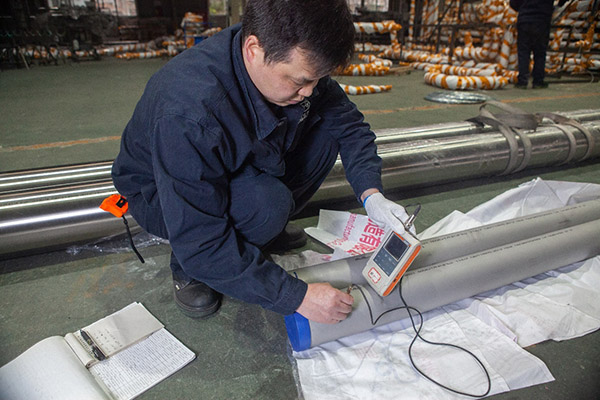

Metallic Element Spectroscopic Analyzer

Ferrite Detector

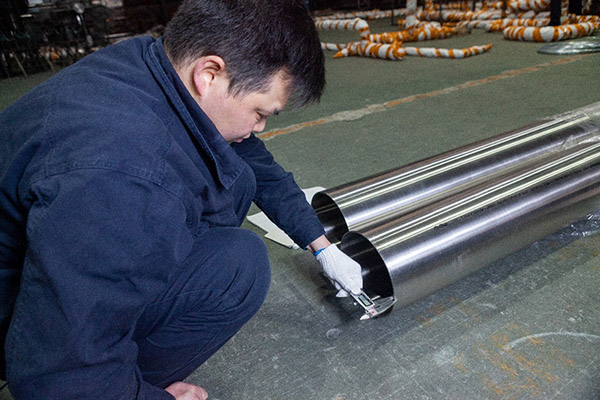

OD and wall thickness inspection

Cleaning Room

Ultrasonic Cleaning Instrument

High Temperature and Pressure Cleaning Machine of Pipe

Drying Room of Heated Pure Nitrogen

Analyzer of Oil Concentration

Pipe Bevelling Machine for Welding

Independent Winding Room of Insulation Material

Argon Fluoride Welding Machine & Area

Vacuum Leak Detectors of Helium Mass Spectrometry

Weld Internal Forming Endoscope

X-ray Nondestructive Inspection Room

X-ray Nondestructive Inspector

Storage of Pressure Unit

Compensator Dryer

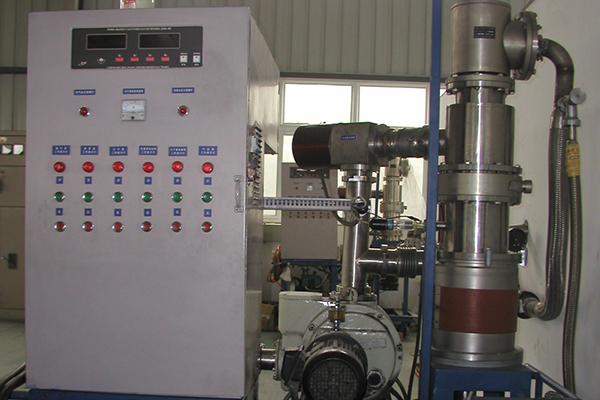

Vacuum Tank of Liquid Nitrogen

Vacuum Machine