Ever wonder how they make those impossibly tiny chips? Precision is everything, and temperature control is a major key. That’s where Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses coupled with special cryogenic equipment come in. They’re the unsung heroes of semiconductor manufacturing, enabling the tech we all use.

Chip making often relies on super-cold liquids like liquid nitrogen (LN2) to control reactions and create specialized environments for etching and deposition – processes so precise they’re measured on an atomic scale!

To get these icy fluids where they need to go without boiling away, engineers use Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses. Think of them like super-thermoses, minimizing heat transfer and keeping the liquids frosty.

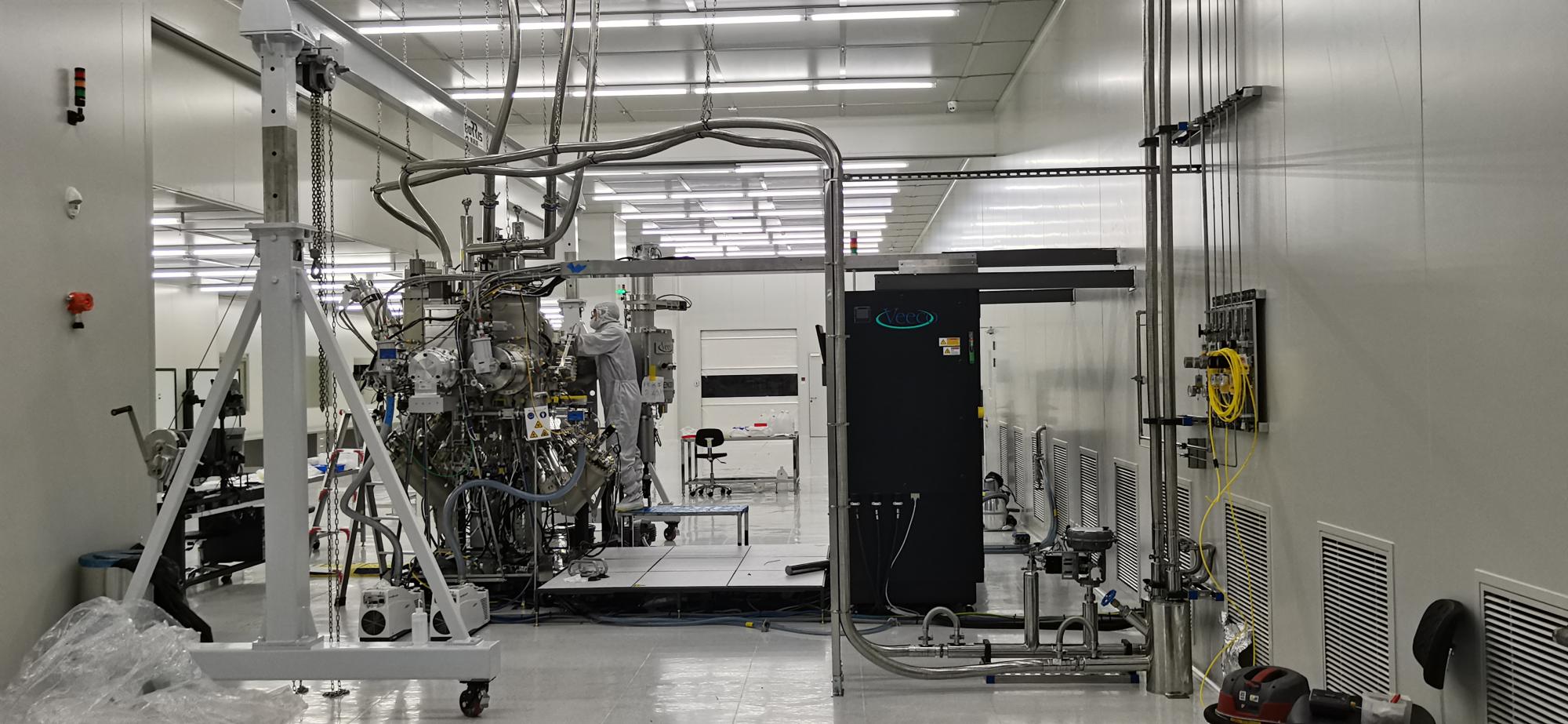

But it’s more than just pipes. Cryogenic equipment integrates with Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses to create cold traps, ultra-high vacuums, and dedicated cooling systems.

It’s not easy, though. Fighting heat leak, choosing materials that can withstand the cold, and detecting tiny leaks are constant challenges. And yes, all this specialized Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses and cryogenic equipment isn’t cheap! However, what is, in the grand scheme?

Ultimately, Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses and the associated cryogenic equipment are vital for modern chip production. They may be unseen, but they make the impossible possible.

Post time: Aug-06-2025