We all know how crucial it is to move super-cold stuff safely and efficiently, right? Think vaccines, rocket fuel, even the stuff that keeps MRI machines humming. Now, imagine pipes and hoses that don’t just carry this ultra-cold cargo, but actually tell you what’s going on inside – in real time. That’s the promise of “smart” systems, and more specifically, Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs) loaded with sensors. Forget guesswork; this is about having eyes and ears on your cryo system, 24/7.

So, what’s the big deal with jamming sensors into Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs), anyway? Well, for starters, it’s like giving your system a constant health check. These sensors continuously monitor temperature, pressure, vacuum – even the tiniest strains on the material. Instead of waiting for something to go wrong, operators get a heads-up before things go south.

Think of it like this: imagine you’re driving a car, and the dashboard only showed you the speed. You’d be missing a lot of vital information! Similarly, just knowing that cryo fluids are flowing through Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs) isn’t enough. You need to know how well they’re flowing, if there are any leaks, or if the insulation is starting to fail.

And that data helps optimize everything. By tracking temperature along the Vacuum Insulated Pipes (VIPs), you can find spots that tend to let in heat, causing liquid to boil-off and be wasted. This precise data allows you to focus maintenance in the right spot. Pressure sensors can also identify flow obstructions, saving you the money and resources.

Of course, with great power comes responsibility. By keeping tabs on that temperature and pressure, these systems can spot conditions that might trigger a major failure, thus enhancing the safety. It’s like a guardian angel, looking for the signs.

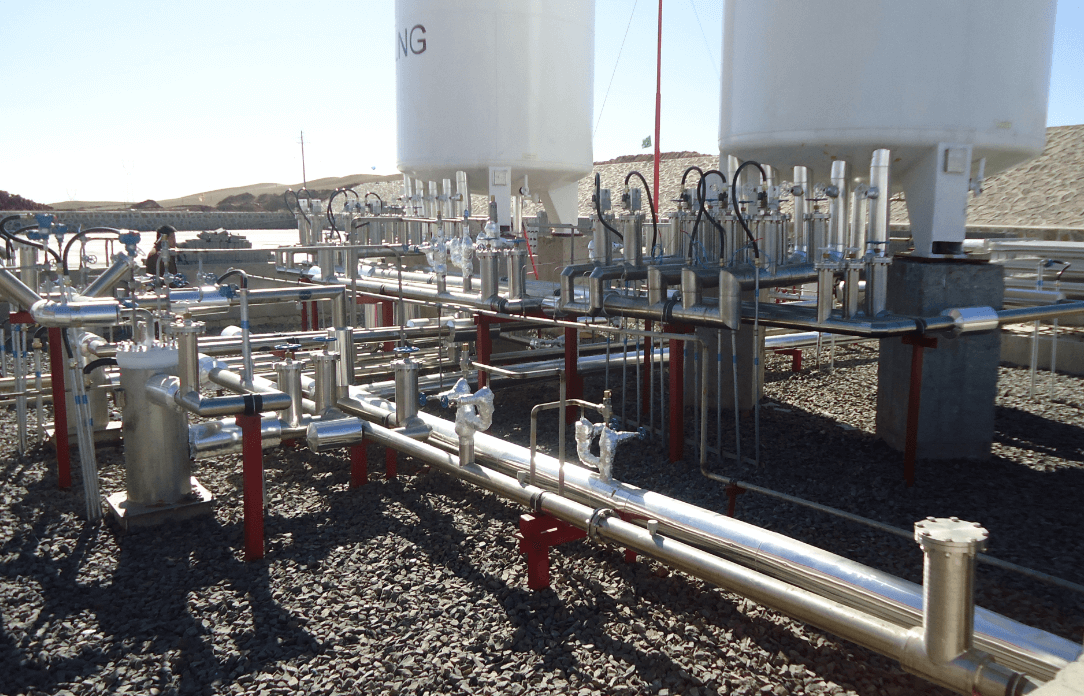

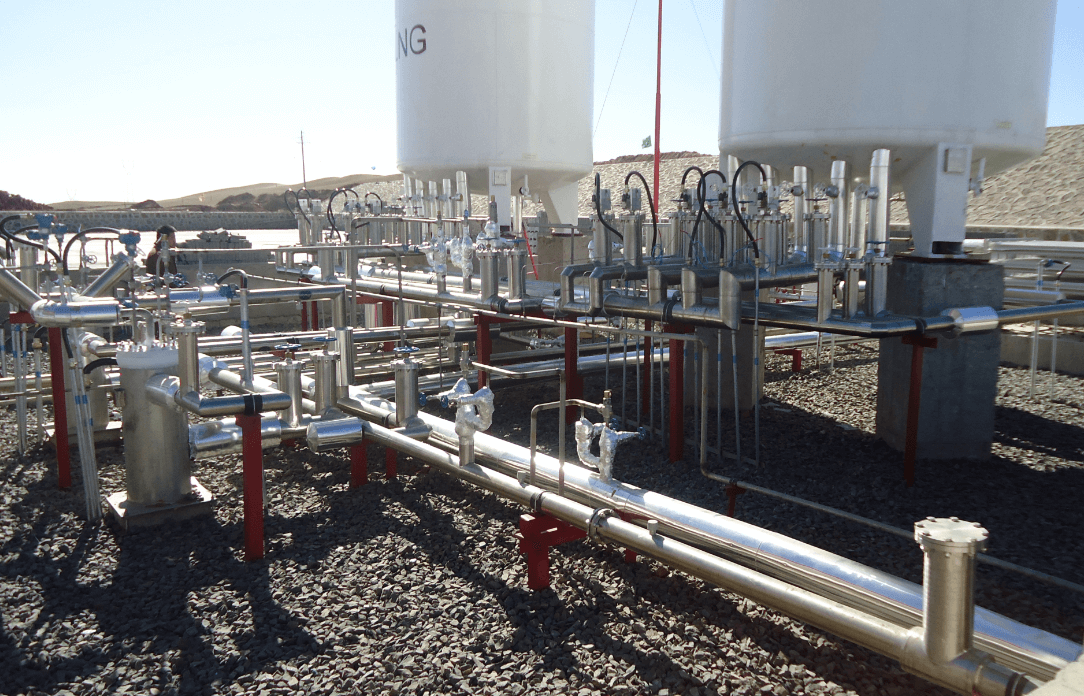

These sensor-equipped Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs) aren’t just a lab curiosity, either. They’re already popping up in places like rocket launchpads, factories that churn out industrial gasses, and even high-tech research labs. Looking ahead, expect to see even more sophisticated systems, with wireless data transmission and the ability to sniff out specific gas leaks before they become a problem.

Bottom line? Smart Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses (VIHs) are changing the game in cryogenic fluid transfer. By giving us unprecedented control and awareness, they’re paving the way for a future that’s not just cold, but also efficient, reliable, and safe. They are paving the way for the efficient transportation of cold gasses and other materials.

Post time: Aug-14-2025