Maintaining an effective vacuum is absolutely critical in cryogenic and industrial environments—there’s no room for sloppiness. A Dynamic Vacuum Pump System is the real backbone here, constantly extracting gas molecules from sealed chambers to ensure low-pressure, stable conditions. Unlike static setups, dynamic pumps don’t just sit back and hope for the best—they’re actively monitoring and adjusting vacuum levels in real time. That’s essential for stuff like cryogenic storage, semiconductor work, or any high-vacuum lab process where a pressure dip spells disaster.

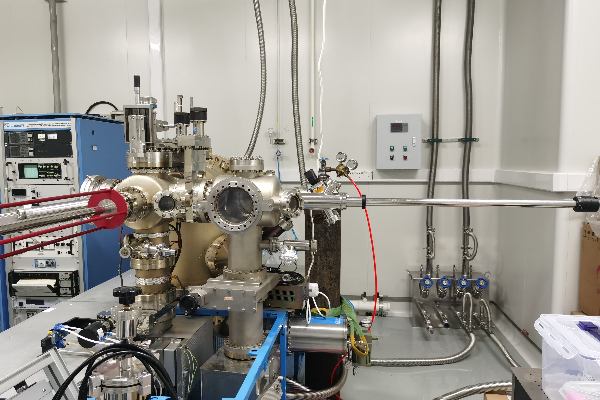

These systems usually combine multiple pump types—rotary vane, turbo molecular, backing pumps—all integrated with smart control units that track pressure and flow. The modular approach isn’t just for show; it lets you scale or tweak the system to match whatever operational demands come your way. From lab benches to heavy-duty industrial lines, these setups adapt without missing a beat.

Dynamic systems beat traditional pumps hands down when it comes to consistency. They keep pressure rock-steady, even if your application load fluctuates. That’s crucial for keeping cryogenic liquids properly insulated and avoiding unplanned downtime. Thanks to advanced control algorithms, you get optimized pump performance, solid energy savings, and less mechanical stress on your expensive gear—think Vacuum Insulated Pipes (VIPs), tanks, and Phase Separators. And if your process changes? Just reconfigure the modules—no major overhaul required.

You’ll see these systems everywhere in cryogenics: LN₂ and LHe storage,Vacuum Insulated Pipes (VIPs), and Phase Separators setups all rely on dynamic vacuum. By minimizing heat transfer and preventing cryogen boil-off, they help maintain those ultra-low temps everyone’s after. In broader industry—vacuum distillation, coating, semiconductor fab—the need for tight pressure control is just as intense, directly impacting quality and yield.

But don’t just grab any system off the shelf. Picking the right Dynamic Vacuum Pump System means nailing down your required vacuum level, pumping speed, compatibility with cryogenic fluids, and integration with whatever pipelines or equipment you’ve got. Get the sizing and maintenance right, and you’ll boost efficiency, keep costs in check, and extend system life.

In short, Dynamic Vacuum Pump Systems aren’t optional—they’re essential tech if you want reliable, high-performance vacuum in cryogenic and industrial operations. With the right setup, you secure energy efficiency, stable processes, and longer equipment life across every vacuum-dependent application you run.

Post time: Oct-17-2025