When you think about air separation, you probably picture massive towers chilling air to make oxygen, nitrogen, or argon. But behind the scenes of these industrial giants, there’s a critical, often overlooked technology keeping everything running smoothly: Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses. These aren’t just plumbing; they’re precision-engineered systems vital for the efficiency and safety of every modern Air Separation unit (ASU).

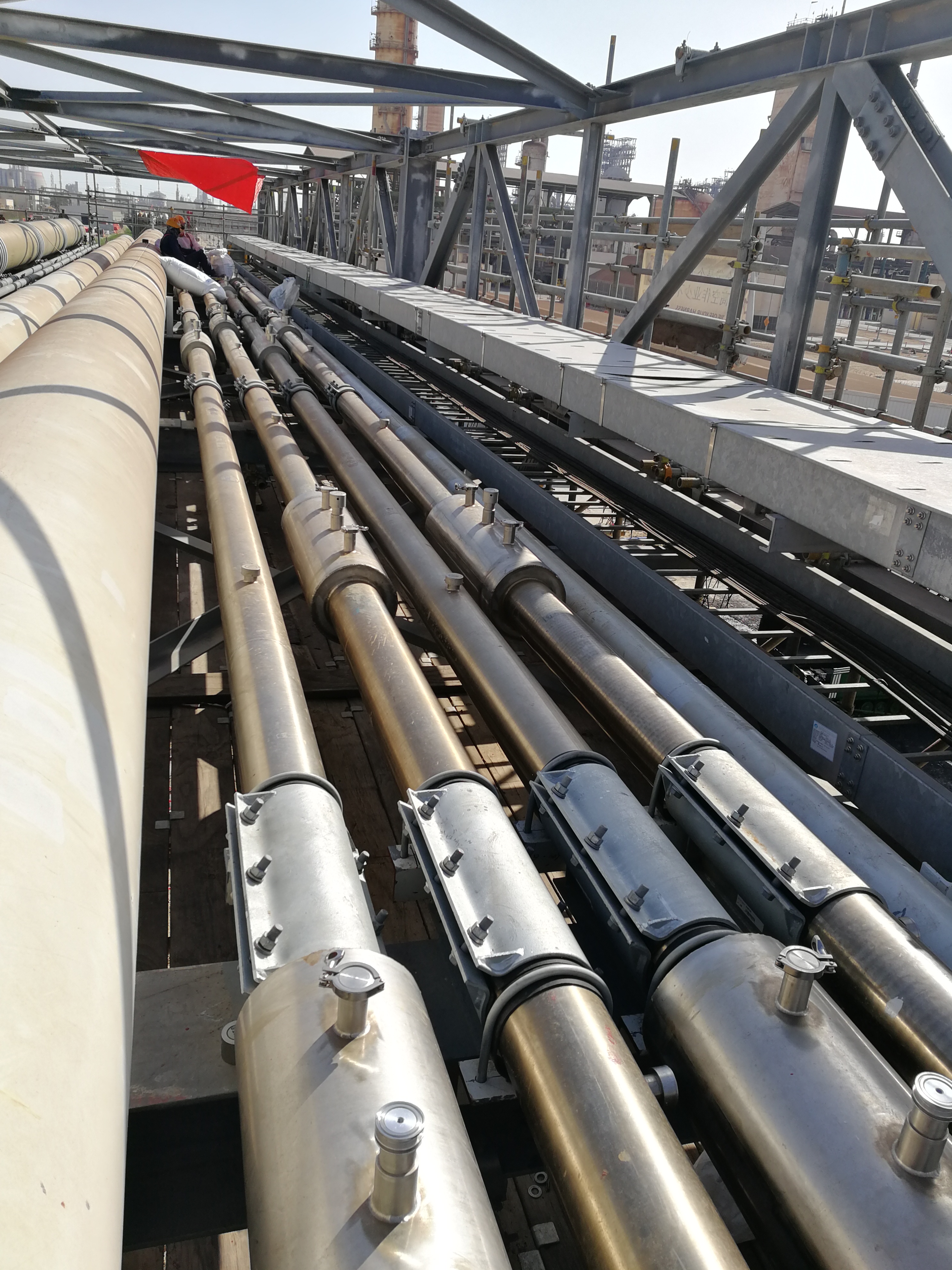

Let’s be clear: cryogenics – the science of extreme cold – is what makes air separation possible. We’re talking temperatures plunging below -180°C (-292°F) to liquefy air. The biggest challenge? Keeping that extreme cold in. Ambient heat is the enemy, constantly trying to warm up and vaporize those precious cryogenic liquids like liquid nitrogen (LN2) and liquid oxygen (LOX). This is precisely where the magic of Vacuum Insulated Pipes (VIPs) comes into play. Think of them as super-powered thermos flasks. By creating a vacuum jacket between the inner and outer walls of the pipe, they create an incredible barrier against heat. The better these Vacuum Insulated Pipes (VIPs) perform, the less energy is wasted, and the more efficient the entire ASU becomes.

Now, what about when things need to move? That’s where Vacuum Insulated Hoses become indispensable. They offer that crucial flexibility for connecting everything – from the main ASU output to storage tanks, linking different process stages, or facilitating those tricky maintenance tasks and refills. Unlike regular hoses, these Vacuum Insulated Hoses maintain that vital cryogenic cold chain. Their robust design prevents any “cold loss” and, crucially, protects both personnel and equipment from the risk of severe cold burns. If you’re running an air separation facility, the reliability of your Vacuum Insulated Hoses is absolutely non-negotiable; a failure here means downtime, inefficiency, and potential safety incidents.

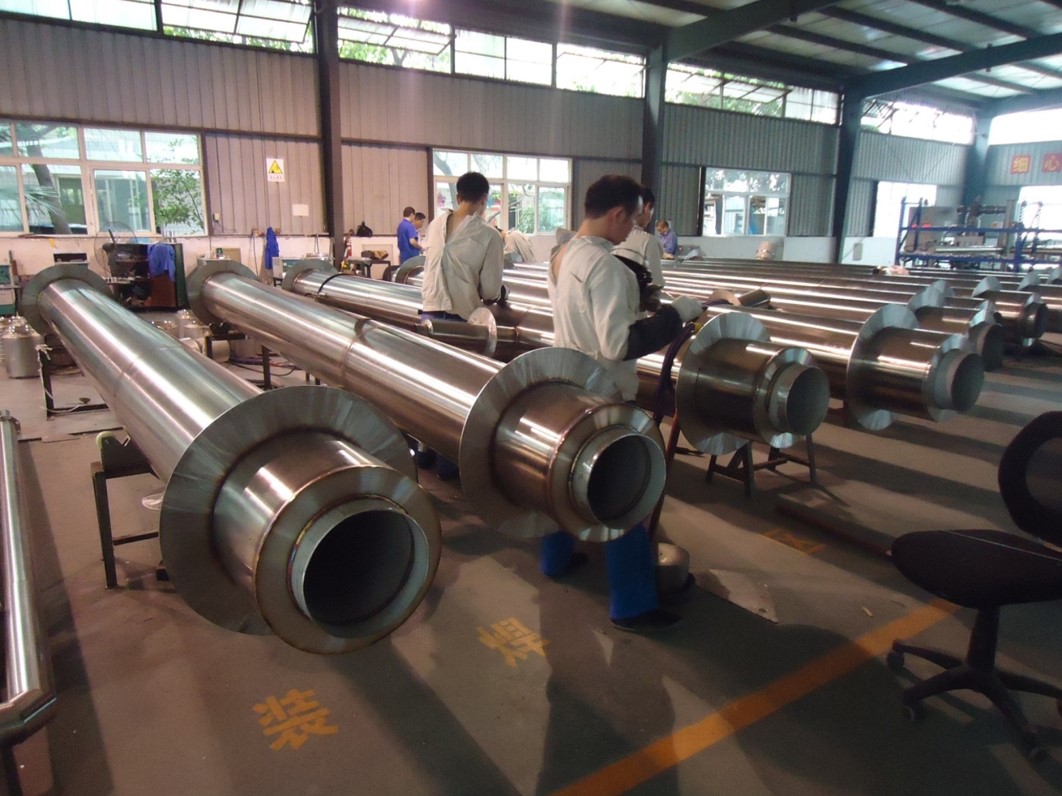

The pressure is always on in this industry to boost efficiency and cut costs. This naturally puts a spotlight on the quality and specification of the Vacuum Insulated Pipes (VIPs) and Vacuum Insulated Hoses used. Manufacturers are constantly innovating, refining materials and construction techniques to make these components even more durable and effective. For any plant operator, selecting top-tier Vacuum Insulated Pipes (VIPs) and dependable Vacuum Insulated Hoses isn’t just a good idea; it’s a strategic investment that pays dividends in product purity, operational uptime, and worker safety. The seamless flow of gases in an ASU truly hinges on the robust performance delivered by these critical cryogenic transfer solutions.

Post time: Jul-24-2025