Hot-selling Pressure Vacuum Vent Valve - Vacuum Insulated Flow Regulating Valve – Holy

Hot-selling Pressure Vacuum Vent Valve - Vacuum Insulated Flow Regulating Valve – Holy Detail:

Product Application

HL Cryogenic Equipment’s vacuum jacketed valves, vacuum jacketed pipe, vacuum jacketed hoses and phase separators are processed through a series of extremely rigorous processes for the transport of liquid oxygen, liquid nitrogen, liquid argon, liquid hydrogen, liquid helium, LEG and LNG, and these products are serviced for cryogenic equipment (e.g. cryogenic tanks, dewars and coldboxes etc.) in industries of air separation, gases, aviation, electronics, superconductor, chips, hospital, pharmacy, bio bank, food & beverage, automation assembly, rubber products and scientific research etc.

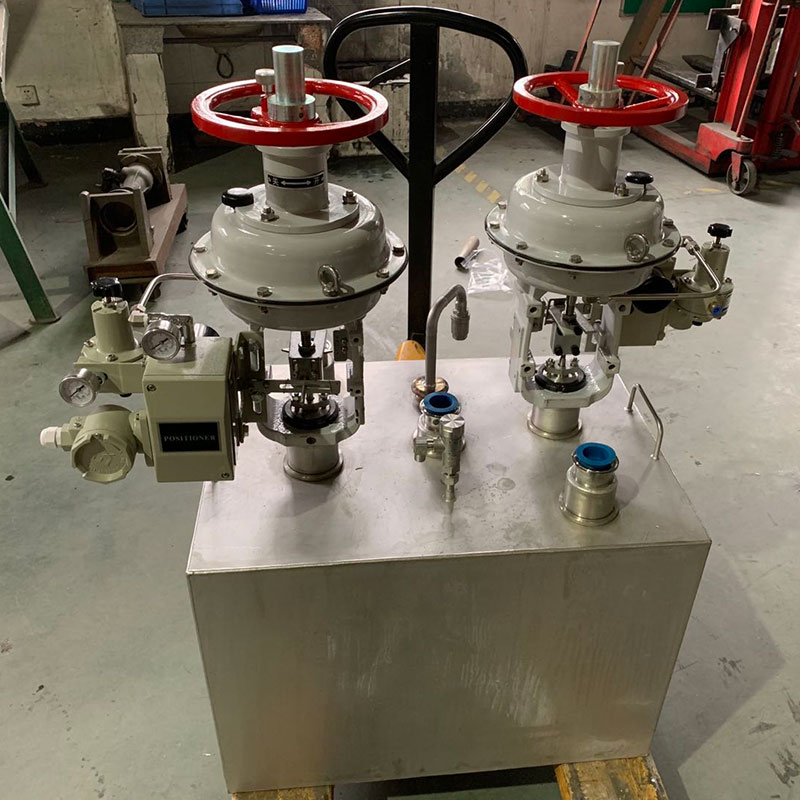

Vacuum Insulated Flow Regulating Valve

The Vacuum Insulated Flow Regulating Valve, namely Vacuum Jacketed Flow Regulating Valve, is widely used control the quantity, pressure and temperature of cryogenic liquid according to the requirements of terminal equipment.

Compared with the VI Pressure Regulating Valve, the VI Flow Regulating Valve and PLC system can be intelligent real-time control of cryogenic liquid. According to the liquid condition of terminal equipment, adjust the valve opening degree in real time to meet the needs of customers for more accurate control. With the PLC system for real-time control, the VI Pressure Regulating Valve needs air source as power.

In the manufacturing plant, VI Flow Regulating Valve and the VI Pipe or Hose are prefabricated into one pipeline, without on-site pipe installation and insulation treatment.

The vacuum jacket part of the VI Flow Regulating Valve may be in the form of a vacuum box or a vacuum tube depending on field conditions. However, no matter what form, it is to better achieve the function.

About VI valve series more detailed and personalized questions, please contact HL cryogenic equipment directly, we will serve you wholeheartedly!

Parameter Information

| Model | HLVF000 Series |

| Name | Vacuum Insulated Flow Regulating Valve |

| Nominal Diameter | DN15 ~ DN40 (1/2″ ~ 1-1/2″) |

| Design Temperature | -196℃~ 60℃ |

| Medium | LN2 |

| Material | Stainless Steel 304 |

| On-site Installation | No, |

| On-site Insulated Treatment | No |

HLVP000 Series, 000 represents the nominal diameter, such as 025 is DN25 1″ and 040 is DN40 1-1/2″.

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for Hot-selling Pressure Vacuum Vent Valve - Vacuum Insulated Flow Regulating Valve – Holy , The product will supply to all over the world, such as: United States, Sheffield, Benin, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let's enjoy it!" Change for the better! Are you ready?

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!