Company History

1992

Founded in 1992, Chengdu Holy Cryogenic Equipment Co., Ltd. launched the HL Cryogenics brand, which has been actively serving the cryogenic industry ever since.

1997

Between 1997 and 1998, HL Cryogenics became a qualified supplier for China’s two leading petrochemical companies, Sinopec and China National Petroleum Corporation (CNPC). For these clients, the company developed a large-diameter (DN500), high-pressure (6.4 MPa) vacuum insulation pipeline system. Since then, HL Cryogenics has maintained a dominant share of China’s vacuum insulation piping market.

2001

To standardize its quality management system, ensure product and service excellence, and align quickly with international standards, HL Cryogenics achieved ISO 9001 quality management system certification.

2002

Entering the new century, HL Cryogenics set its sights on bigger ambitions, investing in and constructing a facility of over 20,000 m². The site includes two administrative buildings, two workshops, a non-destructive inspection (NDE) building, and two dormitories.

2004

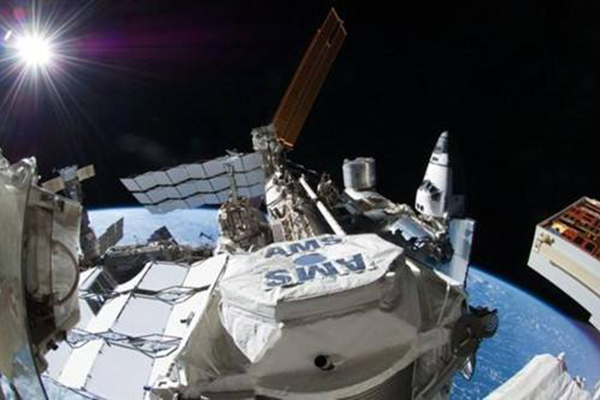

HL Cryogenics contributed to the Cryogenic Ground Support Equipment System for the International Space Station’s Alpha Magnetic Spectrometer (AMS) project, led by Nobel laureate Professor Samuel Chao Chung Ting in collaboration with the European Organization for Nuclear Research (CERN), along with 15 countries and 56 research institutes.

2005

From 2005 to 2011, HL Cryogenics successfully passed on-site audits by leading international gas companies—including Air Liquide, Linde, Air Products (AP), Messer, and BOC—becoming a qualified supplier for their projects. These companies authorized HL Cryogenics to manufacture in accordance with their standards, enabling HL to deliver solutions and products for air separation plants and gas application projects.

2006

HL Cryogenics began a comprehensive partnership with Thermo Fisher to develop biological-grade vacuum insulation piping systems and supporting equipment. This collaboration has attracted a wide range of customers in pharmaceuticals, cord blood storage, gene sample preservation, and other biopharmaceutical sectors.

2007

Recognizing the demand for MBE liquid nitrogen cooling systems, HL Cryogenics assembled a specialized technical team to tackle the challenges and successfully developed an MBE-dedicated liquid nitrogen cooling system along with a pipeline control system. These solutions have been successfully implemented in numerous enterprises, universities, and research institutes.

2010

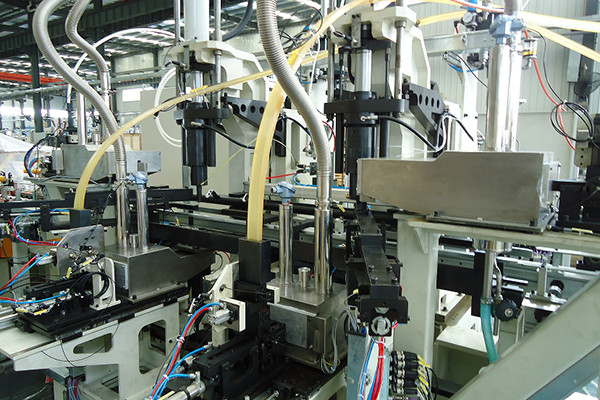

With more international automobile brands establishing factories in China, the demand for cold assembly of automobile engines has grown significantly. HL Cryogenics recognized this trend, invested in R&D, and developed advanced cryogenic piping equipment and control systems to meet industry needs. Notable customers include Coma, Volkswagen, and Hyundai.

2011

In the global effort to reduce carbon emissions, the search for clean energy alternatives to petroleum has intensified—LNG (Liquefied Natural Gas) being one of the most prominent options. To meet this growing demand, HL Cryogenics has introduced vacuum insulation pipelines and supporting vacuum valve control systems for LNG transfer, contributing to the advancement of clean energy. To date, HL Cryogenics has participated in the construction of over 100 gas filling stations and more than 10 liquefaction plants.

2019

After a six-month audit in 2019, HL Cryogenics fully met the customer’s requirements and subsequently provided products, services, and solutions for SABIC projects.

2020

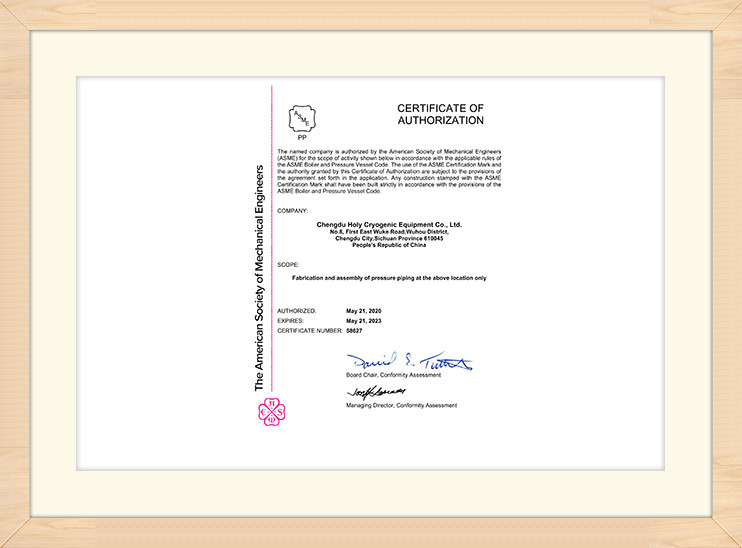

To advance its internationalization, HL Cryogenics invested nearly a year of effort to secure authorization from the ASME Association, ultimately obtaining its ASME certification.

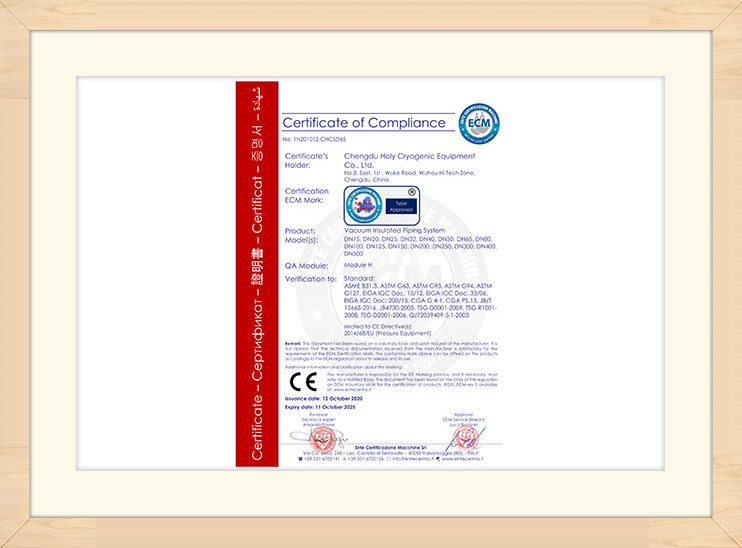

2020

To further advance its internationalization, HL Cryogenics applied for and obtained CE certification.